Our Alloy

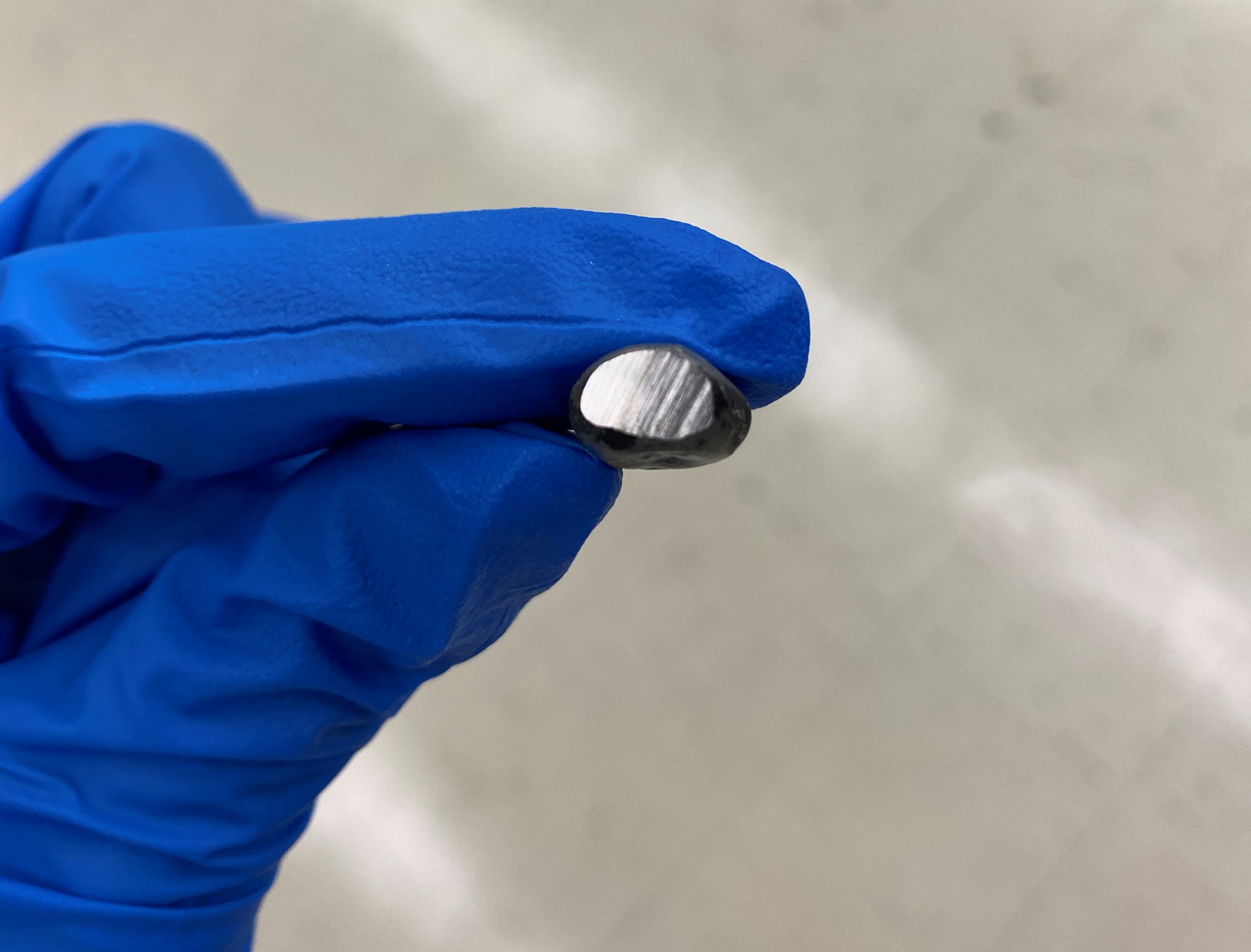

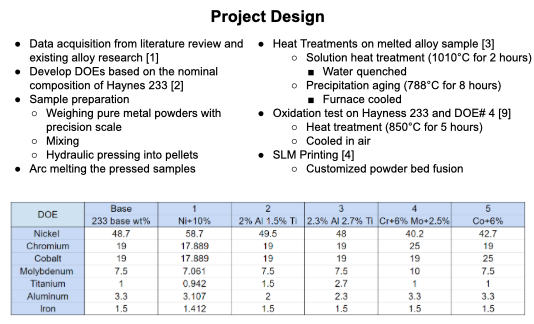

The goal of the Relativity Space project is to select a nickel superalloy in wire or powder format that can improve the performance and additive manufacturing processing for the fully 3D printed rocket application. The selected material will be characterized with different techniques to analyze and improve its performance. The nickel superalloy for this application can be in powder form and will be used with the powder bed fusion method, or it can also be in wire form with wire arc additive manufacturing method.

Our Approach

We will first do a literature review to learn the background of the nickel alloys in the aerospace industry and the current use of nickel alloys in space flight applications. Once the literature review is done, we plan to make a preliminary list of alloys that meet the broad criteria needed for our application. This list will be narrowed down using thermocalc, a software used to understand and predict material properties. Once the list is narrowed down, we will begin work with physical samples. The physical samples of the chosen alloys will be characterized with methods such as SEM and XRD by our team to better study their properties. This in depth study will allow us to choose our final alloy. This final alloy can be post-treated to further improve the properties to be more exact to our requirement. This final alloy will be 3D printed at the Relativity Space facility to ensure that their additive manufacturing machines can work with the chosen alloy.